Page 76 - 台玻集團2019 CSR英文版

P. 76

Ch1 CH2 CH3 CH4 CH5 CH6

Sustainability Steady Operation, Excellent Service Quality Sustainable Safe Workplace Social and

Communication Integrity Governance & Innovative Products Operation & Trusted Growth Community Care

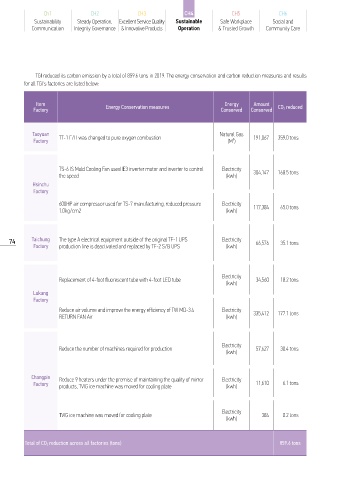

TGI reduced its carbon emission by a total of 859.6 tons in 2019. The energy conservation and carbon reduction measures and results

for all TGI's factories are listed below:

Item Energy Amount

Factory Energy Conservation measures Conserved Conserved CO 2 reduced

Taoyuan Natural Gas

Factory TT-1 F/H was changed to pure oxygen combustion (M ) 191,067 359.0 tons

3

TS-6 IS Mold Cooling Fan used IE3 inverter motor and inverter to control Electricity 304,147 168.5 tons

the speed (kwh)

Hsinchu

Factory

600HP air compressor used for TS-7 manufacturing, reduced pressure Electricity 117,384 65.0 tons

1.0kg/cm2 (kwh)

74 Taichung The type A electrical equipment outside of the original TF-1 UPS Electricity 66,576 35.1 tons

Factory production line is deactivated and replaced by TF-2 S/B UPS (kwh)

Electricity

Replacement of 4-foot fluorescent tube with 4-foot LED tube 34,560 18.2 tons

(kwh)

Lukang

Factory

Reduce air volume and improve the energy efficiency of TW MD-3.4 Electricity 335,412 177.1 tons

RETURN FAN Air (kwh)

Electricity

Reduce the number of machines required for production 57,627 30.4 tons

(kwh)

Changpin Reduce 9 heaters under the premise of maintaining the quality of mirror Electricity

Factory products, TVIG ice machine was moved for cooling plate (kwh) 11,610 6.1 tons

Electricity

TVIG ice machine was moved for cooling plate 384 0.2 tons

(kwh)

Total of CO 2 reduction across all factories (tons) 859.6 tons