Page 79 - 台玻集團2019 CSR英文版

P. 79

2019 Corporate Sustainability Report TAIWANGLASS

4.3 Green Production & Management.

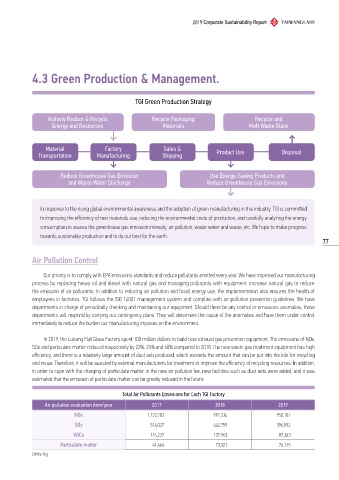

TGI Green Production Strategy

Actively Reduce & Recycle Recycle Packaging Recycle and

Energy and Resources Materials Melt Waste Glass

Material Factory Sales &

Transportation Manufacturing Shipping Product Use Disposal

Reduce Greenhouse Gas Emission Use Energy-Saving Products and

and Waste Water Discharge Reduce Greenhouse Gas Emissions

In response to the rising global environmental awareness and the adoption of green manufacturing in this industry, TGI is committed

to improving the efficiency of raw materials use, reducing the environmental costs of production, and carefully analyzing the energy

consumption to assess the greenhouse gas emission intensity, air pollution, waste water and waste, etc. We hope to make progress

towards sustainable production and to do our best for the earth.

77

Air Pollution Control

Our priority is to comply with EPA'emissions standards and reduce pollutants emitted every year. We have improved our manufacturing

process by replacing heavy oil and diesel with natural gas and managing pollutants with equipment. increase natural gas to reduce

the emission of air pollutants. In addition to reducing air pollution and fossil energy use, the implementation also ensures the health of

employees in factories. TGI follows the ISO 14001 management system and complies with air pollution prevention guidelines. We have

departments in charge of periodically checking and maintaining our equipment. Should there be any control or emissions anomalies, these

departments will respond by carrying out contingency plans. They will determine the cause of the anomalies and have them under control

immediately to reduce the burden our manufacturing imposes on the environment.

In 2019, the Lukang Flat Glass Factory spent 100 million dollars to build new exhaust gas prevention equipment. The emissions of NOx,

SOx and particulate matter reduced respectively by 22%, 25% and 60% compared to 2018. The new waste gas treatment equipment has high

efficiency, and there is a relatively large amount of dust ash produced, which exceeds the amount that can be put into the kiln for recycling

and reuse. Therefore, it will be assisted by external manufacturers for treatment or improve the efficiency of recycling resources. In addition,

in order to cope with the charging of particulate matter in the new air pollution fee, new facilities such as dust nets were added, and it was

estimated that the emission of particulate matter can be greatly reduced in the future.

Total Air Pollutants Emissions for Each TGI Factory

Air pollution evaluation item/year 2017 2018 2019

NOx 1,122,783 997,334 950,107

SOx 514,037 442,759 396,592

VOCs 114,237 137,963 87,363

Particulate matter 41,466 73,321 76,115

Units: kg