Page 25 - 台玻集團2019 CSR英文版

P. 25

2019 Corporate Sustainability Report TAIWANGLASS

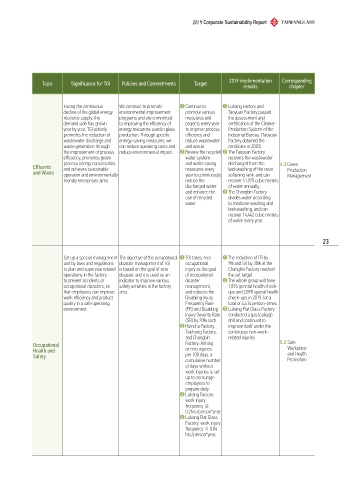

Topic Significance for TGI Policies and Commitments Target 2019 implementation Corresponding

chapter

results

Facing the continuous We continue to promote 1 Continue to 1 Lukang Factory and

decline of the global energy environmental improvement promote various Taoyuan Factory passed

resource supply, the programs and are committed measures and the assessment and

demand side has grown to improving the efficiency of projects every year certification of the Cleaner

year by year; TGI actively energy resources used in glass to improve process Production System of the

promotes the reduction of production. Through specific efficiency and Industrial Bureau. (Taoyuan

wastewater discharge and energy-saving measures, we reduce wastewater Factory obtained the

waste generation through can reduce operating costs and and waste. certificate in 2020)

the improvement of process reduce environmental impact. 2 Review the recycled 2 The Taoyuan Factory

efficiency, promotes green water system recovers the wastewater

process energy conservation, and water saving discharged from the 4.3 Green

Effluents and achieves sustainable measures every backwashing of the resin

and Waste operation and environmentally year to continuously softening tank, and can Production

Management

friendly enterprises aims. reduce the recover 41,975 cubic meters

discharged water of water annually.

and enhance the 3 The Changbin Factory

use of recycled divides water according

water. to medicine washing and

backwashing, and can

recover 14,442 cubic meters

of water every year.

23

Set up a special management The objective of the occupational 1 TGI takes zero 1 The reduction of FR by

unit by laws and regulations disaster management of TGI occupational 9% and SR by 30% at the

to plan and supervise related is based on the goal of zero injury as the goal Changbin Factory reached

operations in the factory disaster, and it is used as an of occupational the set target.

to prevent accidents or indicator to improve various disaster 2 The whole group will have

occupational disasters, so safety activities in the factory management, 1,876 general health check-

that employees can improve area. and reduces the ups and 2,898 special health

work efficiency and product Disabling Injury check-ups in 2019, for a

quality in a safe operating Frequency Rate total of 4,414 person-times.

environment. (FR) and Disabling 3 Lukang Flat Glass Factory

Injury Severity Rate conducted a gas leakage

(SR) by 20% each. drill and continued to

2 Hsinchu Factory, improve itself under the

Taichung Factory, continuous non-work-

and Changbin related injuries.

Occupational Factory: Aiming 5.3 Safe

Health and at zero injuries Workplace

Safety per 100 days, a and Health

cumulative number Promotion

of days without

work injuries is set

up to encourage

employees to

prepare daily.

3 Lukang Factory:

work injury

frequency Ù

0.2hrs/person*year.

4 Lukang Flat Glass

Factory: work injury

frequency Ù 0.04

hrs/person*year.