Page 97 - 2017台玻CSR_英文_全含封面1002 (1)

P. 97

4.3 Green Innovation

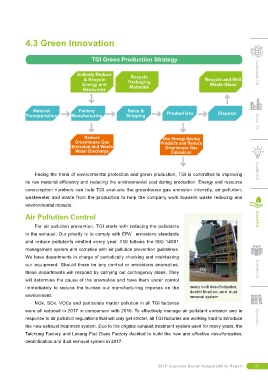

TGI Green Production Strategy

Actively Reduce Recycle Sustainable TGI

& Recycle Packaging Recycle and Melt

Energy and Materials Waste Glass

Resources

Material Factory Sales & Product Use Disposal

Transportation Manufacturing Shipping About TGI

Reduce Use Energy-Saving

Greenhouse Gas Products and Reduce

Emission and Waste Greenhouse Gas

Water Discharge Emissions

Facing the trend of environmental protection and green production, TGI is committed to improving Quality TGI

its raw material efficiency and reducing the environmental cost during production. Energy and resource

consumption numbers can help TGI evaluate the greenhouse gas emission intensity, air pollution,

wastewater and waste from the production to help the company work towards waste reducing and

environmental impacts.

Air Pollution Control Green TGI

For air pollution prevention, TGI starts with reducing the pollutants

in the exhaust. Our priority is to comply with EPA§emissions standards

and reduce pollutants emitted every year. TGI follows the ISO 14001

management system and complies with air pollution prevention guidelines.

We have departments in charge of periodically checking and maintaining

our equipment. Should there be any control or emissions anomalies,

these departments will respond by carrying out contingency plans. They Friendly TGI

will determine the cause of the anomalies and have them under control

immediately to reduce the burden our manufacturing imposes on the newly built desulfurization,

denitrification and dust

environment. removal system

NOx, SOx, VOCs and particulate matter pollution in all TGI factories

were all reduced in 2017 in comparison with 2016. To effectively manage air pollutant emission and in

response to air pollution regulations that will only get stricter, all TGI factories are working hard to introduce Appendix

the new exhaust treatment system. Due to the original exhaust treatment system used for many years, the

Taichung Factory and Lukang Flat Glass Factory decided to build the new and effective desulfurization,

denitrification and dust removal system in 2017.

2017 Coporate Social Responsibility Report 95