Page 93 - 2017台玻CSR_英文_全含封面1002 (1)

P. 93

CO 2

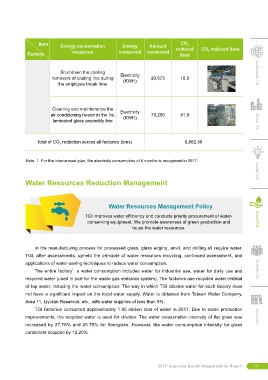

Item Energy conservation Energy Amount reduced CO 2 reduced (ton)

Factory measures conserved conserved (ton)

Shut down the coating Sustainable TGI

removers of coating line during Electricity 20,573 10.9

the employee break time (KWH)

Cleaning and maintenance the Electricity

air conditioning heater in the 1st (KWH) 79,200 41.8

laminated glass assembly line About TGI

Total of CO 2 reduction across all factories (tons) 6,882.38

Note: 1. For the inter-annual plan, the electricity consumption of 6 months is recognized in 2017.

Water Resources Reduction Management Quality TGI

Water Resources Management Policy

TGI improves water efficiency and conducts priority procurement of water-

conserving equipment. We promote awareness of green production and Green TGI

reuse the water resources.

In the manufacturing process for processed glass, glass edging, anvil, and drilling all require water.

TGI, after assessments, upheld the principle of water resources recycling, continued assessment, and

applications of water-saving techniques to reduce water consumption.

The entire factory§s water consumption includes water for industrial use, water for daily use and Friendly TGI

recycled water (used in part for the waste gas emission system). The factories use recycled water instead

of tap water, reducing the water consumption. The way in which TGI obtains water for each factory does

not have a significant impact on the local water supply. Water is obtained from Taiwan Water Company,

Area 11, Liyutan Reservoir, etc., with water supplies of less than 5%.

TGI factories consumed approximately 1.95 million tons of water in 2017. Due to some production

improvements, the recycled water is used for dilution. The water consumption intensity of flat glass was Appendix

increased by 37.78% and 29.75% for fiberglass. However, the water consumption intensity for glass

containers dropped by 12.20%.

2017 Coporate Social Responsibility Report 91