Page 45 - 台玻集團2019 CSR英文版

P. 45

2019 Corporate Sustainability Report TAIWANGLASS

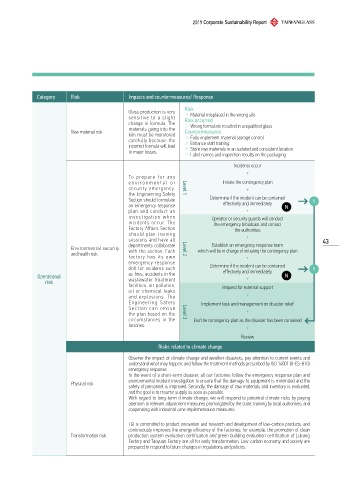

Category Risk Impacts and countermeasures/ Response

Risk

Glass production is very × Material misplaced in the wrong silo

sensitive to a slight Risk occurred

change in formula. The × Wrong formulate resulted in unqualified glass

materials going into the

Raw material risk Countermeasures

kiln must be monitored × Fully implement material storage control

carefully because the × Enhance staff training

incorrect formula will lead × Store raw materials in an isolated and consistent location

to major losses.

× Label names and inspection results on the packaging

Incidents occur

À

To prepare for any

environmental or Initiate the contingency plan

security emergency, Level 1 À

the Engineering Safety

Section should formulate Determine if the incident can be contained Y

an emergency response effectively and immediately N

plan and conduct an À

investigation when Operator or security guards will conduct

incidents occur. The the emergency broadcast and contact

Factory Affairs Section the authorities

should plan training

sessions and have all À 43

departments collaborate Establish an emergency response team

Environmental security with the section. Each Level 2 which will be in charge of initiating the contingency plan

and health risk

factory has its own À

emergency response

drill for incidents such Determine if the incident can be contained Y

effectively and immediately

Operational as fires, accidents in the N

risk wastewater treatment À

facilities, air pollution, Request for external support

oil or chemical leaks

and explosions. The À

Engineering Safety Implement task and management on disaster relief

Section can revise

the plan based on the Level 3 À

circumstances in the End the contingency plan as the disaster has been contained

factories.

À

Review

Risks related to climate change

Observe the impact of climate change and weather disasters, pay attention to current events and

understand what may happen, and follow the treatment methods prescribed by ISO 14001 (8-ES-B10)

emergency response.

In the event of a short-term disaster, all our factories follow the emergency response plan and

environmental incident investigation to ensure that the damage to equipment is minimized and the

Physical risk

safety of personnel is improved. Secondly, the damage of raw materials and inventory is evaluated,

and the goal is to resume supply as soon as possible.

With regard to long-term climate change, we will respond to potential climate risks by paying

attention to relevant adjustment measures promulgated by the state, training by local authorities, and

cooperating with industrial zone implementation measures.

TGI is committed to product innovation and research and development of low-carbon products, and

continuously improves the energy efficiency of the factories; for example, the promotion of clean

Transformation risk production system evaluation certification and green building evaluation certification of Lukang

Factory and Taoyuan Factory are all for early transformation. Low-carbon economy and society are

prepared to respond to future changes in regulations and policies.