Page 52 - 2017台玻CSR_英文_全含封面1002 (1)

P. 52

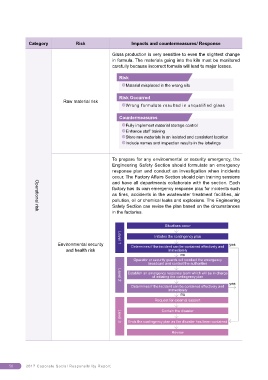

Category Risk Impacts and countermeasures/ Response

Glass production is very sensitive to even the slightest change

in formula. The materials going into the kiln must be monitored

carefully because incorrect formula will lead to major losses.

Risk

Material misplaced in the wrong silo

Risk Occurred

Raw material risk

Wrong formulate resulted in unqualified glass

Countermeasures

Fully implement material storage control

Enhance staff training

Store raw materials in an isolated and consistent location

Include names and inspection results in the labelings

To prepare for any environmental or security emergency, the

Engineering Safety Section should formulate an emergency

response plan and conduct an investigation when incidents

occur. The Factory Affairs Section should plan training sessions

and have all departments collaborate with the section. Each

factory has its own emergency response plan for incidents such

as fires, accidents in the wastewater treatment facilities, air

pollution, oil or chemical leaks and explosions. The Engineering

Safety Section can revise the plan based on the circumstances

in the factories.

Operational risk

Situations occur

Initiates the contingency plan

Environmental security Determines if the incident can be contained effectively and yes

Level 1

and health risk immediately

no

Operator or security guards will conduct the emergency

broadcast and contact the authorities

Establish an emergency response team which will be in charge

of initiating the contingency plan

yes

Level 2

Determines if the incident can be contained effectively and

immediately

no

Request for external support

Contain the disaster

Ends the contingency plan as the disaster has been contained

Level 3

Review

50 2017 Coporate Social Responsibility Report