Page 93 - 2018台玻csr英文1022

P. 93

tem Energy Amount CO reduced Product Water Consumptions (by year)

2

Energy conservation measures 1,600,000 2016

Factory conserved conserved (ton) 1,344,369 1,490,099 Leadership

1,400,000 2017 CH.1 Sustainable Glass

Tungsten light bulb replaced with LED bulb Electricity (kWh) 474.4 262.8 1,200,000 2018

Taichung 1,000,000 1,047,626

Factory With the production conditions, the power of Electricity (kWh) 286,272 158.6

FP2 of F.P.B was reduced from 200kw to 160kw. 800,000 414,907

600,000 464,985

Reduce <T/W>HVACMD-3&MD-4 return air Electricity (kWh) 263,382 139.1 406,312

Lukang volume 400,000 189,890

194,516

Factory TW MD-1.2 RETURN FAN air volume reduction 200,000 0 151,575 CH.2 Ethical

and energy saving improvement Electricity (kWh) 190,728 100.7

Flat Glass Fiberglass Glass Container Operation

Air conditioning equipment for glue production Electricity (kWh) 150,336 79.4

line is closed when not in production

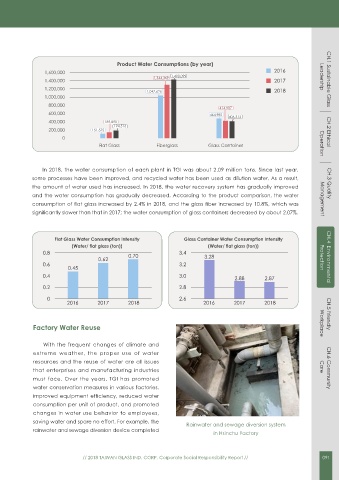

Plated line EDI process water system is only In 2018, the water consumption of each plant in TGI was about 2.09 million tons. Since last year,

Changpin enabled for production needs time Electricity (kWh) 99,060 52.3 some processes have been improved, and recycled water has been used as dilution water. As a result,

Factory CH.3 Quality

Multilayer butyl melter closed on holidays Electricity (kWh) 30,210 16.0 the amount of water used has increased. In 2018, the water recovery system has gradually improved

and the water consumption has gradually decreased. According to the product comparison, the water

Edging and drilling machine reduces daily Electricity (kWh) 56,311 29.7 Management

usage time consumption of flat glass increased by 2.4% in 2018, and the glass fiber increased by 10.8%, which was

significantly slower than that in 2017; the water consumption of glass containers decreased by about 2.07%.

Total of CO2 reduction across all factories (tons)j 5,518.7

Water Resources Reduction Management Flat Glass Water Consumption Intensity Glass Container Water Consumption Intensity

(Water/ flat glass (ton)) (Water/ flat glass (ton))

0.8 0.70 3.4 3.28

Water Resources Management Policy 0.62 Protection CH.4 Environmental

0.6 0.45 3.2

TGI improves water efficiency and conducts priority procurement of water-conserving equipment. 0.4 3.0

We promote awareness of green production and reuse the water resources. 2.88 2.87

0.2 2.8

In the process of manufacturing glass, such 0 2.6

as glass edging, anvil holes, drilling, etc., a large Factory Water Source 2016 2017 2018 2016 2017 2018

amount of water source must be used. We Taiwan Water Corporation CH.5 Friendly

continue to improve water-saving technologies in Taoyuan 2nd Branch Factory Water Reuse Workplace

various factories, evaluate feasible methods and

apply them to reduce water consumption and Hsinchu Dongxing waterworks

With the frequent changes of climate and

achieve the spirit of sustainable water resources. Water Management Area 4, extreme weather, the proper use of water

The water used in each factory can be divided Taichung 1st Branch resources and the reuse of water are all issues CH.6

into business water, domestic water and recycled that enterprises and manufacturing industries Care

water (partially used in the exhaust system), and Lukang/ must face. Over the years, TGI has promoted Community

recycled water is used instead of tap water to Lukang Flat Glass Taiwan Water Corporation

11th Branch water conservation measures in various factories,

reduce the amount of tap water. The water

Changpin improved equipment efficiency, reduced water

withdrawal from each factory in Taiwan has no

consumption per unit of product, and promoted

significant impact on the local water source. The

changes in water use behavior to employees,

water intake is as shown in the right table.

saving water and spare no effort. For example, the Rainwater and sewage diversion system

rainwater and sewage diversion device completed

in Hsinchu Factory

090 // 2018 TAIWAN GLASS IND. CORP. Corporate Social Responsibility Report // // 2018 TAIWAN GLASS IND. CORP. Corporate Social Responsibility Report // 091